Quality

Quality Manufacturing is Our Objective

At Sandip Brass Industries, we take immense pride in our commitment to delivering unparalleled quality in precision parts manufacturing.

Our stringent quality control processes set us apart as a leader in the industry, and our ISO 9001:2015 certified Quality Management System is a testament to our dedication to excellence.

Certified Manufacturers

ISO 9001:2005High Tech Manufacturer

In EuropeOur Quality Control Differentiators

Precision at Every Stage

From raw material inspection to final product evaluation, precision is at the heart of our quality control process. Our skilled technicians utilize advanced equipment and techniques to ensure that each part meets the strictest tolerances and specifications.

ISO 9001:2015 Certified QMS

Our Quality Management System adheres to the globally recognized ISO 9001:2015 standard. This certification is a reflection of our commitment to consistent quality, efficient processes, and continuous improvement.

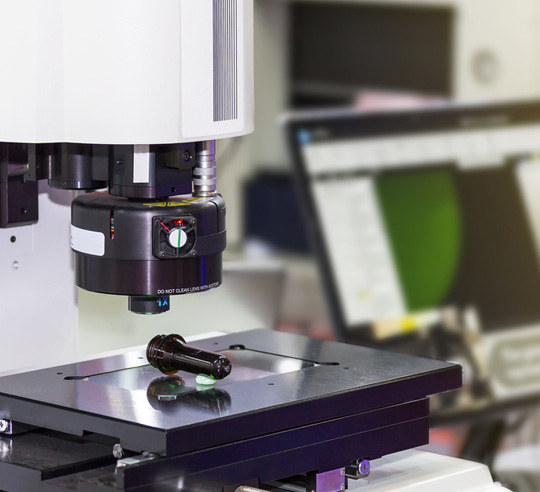

State-of-the-Art Inspection Facilities

Our expansive 10,000+ sq. ft. factory floor houses cutting-edge inspection equipment, including coordinate measuring machines (CMMs), optical comparators, and more. This technology enables us to meticulously verify the dimensions and attributes of each component.

Skilled Quality Professionals

Our dedicated quality control team comprises experienced professionals who possess a keen eye for detail. They are extensively trained to identify even the slightest deviations from quality standards.

Robust Process Validation

We adhere to a comprehensive process validation approach, ensuring that our manufacturing processes consistently yield products of the highest quality. This includes rigorous testing and validation of materials, processes, and equipment.

Embracing Lean Principles (5S):

We adopt Lean manufacturing principles, including the renowned 5S methodology, to ensure an organized and efficient workspace. This commitment to orderliness contributes to consistent quality outcomes.

FAIR, SPC, PPAP, and APQP

We employ an array of industry-recognized practices, including First Article Inspection (FAIR), Statistical Process Control (SPC), Production Part Approval Process (PPAP), and Advanced Product Quality Planning (APQP). These methodologies bolster our ability to deliver components of superior quality and reliability.

Real-time Monitoring and Traceability

Our systems allow us to monitor manufacturing processes in real time and maintain complete traceability for each part. This transparency ensures that any deviations can be swiftly identified and rectified.

Our Quality Assurance Commitment

At Sandip Brass Industries, quality control is not just a process – it's a promise. We are dedicated to exceeding industry benchmarks and offering our clients products that exemplify precision, reliability, and durability. Our continuous pursuit of excellence is underpinned by our ISO 9001:2015 certification, demonstrating our alignment with global quality standards.

In choosing Sandip Brass Industries, you're choosing a partner who prioritizes quality as much as you do. We invite you to experience the difference that our world-class quality control measures make in every precision component we deliver.